Grinding Mill Of Vertical Roller Mill In Cement Plant

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill Grinding roller is core part of vertical mill SYMMEN METAL Casting can provide customized service according to customers' different processing requirements Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc We gained good reputation from customersGrinding Roller Manufacturer From China Symmen Metal Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93 (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, Vertical Roller Mill for Cement, Clinker, Slag, etc Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings The materials such as clinker and gypsum fed into the mill are ground by compressionVertical roller mill for cement grindingChapter 42 Vertical Roller Mills For Finish Grinding Of Cement Vertical roller mill for grinding durbanlizards vertical roller mills for finish grinding industrial efficiency ball mills that are commonly used for finish grinding have high energy demands consuming up to 30 42 kwht clinker depending on the fineness of the cement More DetailsVertical Roller Mills Cement Grinding EXODUS Mining

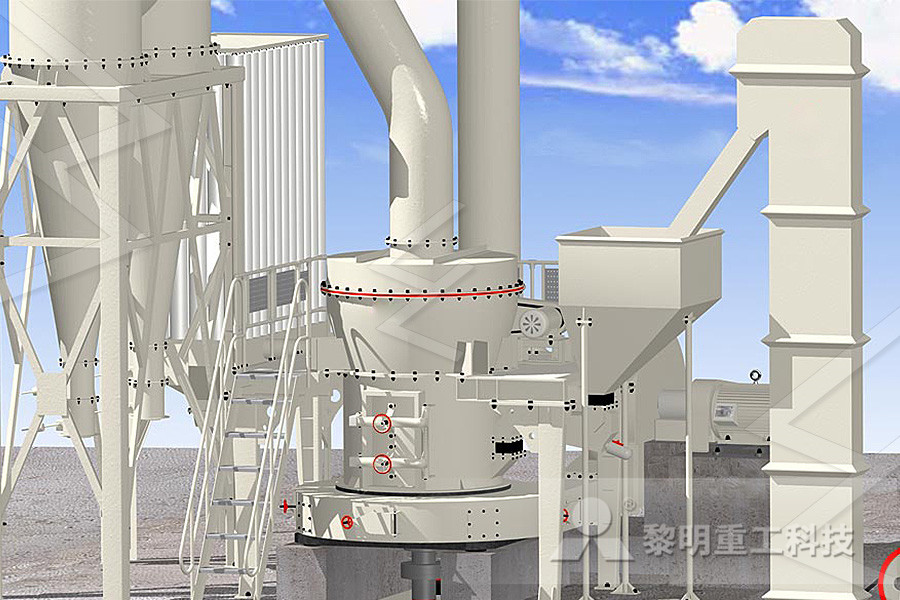

Vertical Grinding Mill, Vertical Roller Mill Powder Making

Vertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the majority ofCement grinding Vertical roller mills versus ball millsVertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plant Because the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power, metallurgy, chemical industry, metalVertical Raw Mill for Cement Raw Meal Grinding in Cement Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Cement Grinding Machine Selection: Vertical Roller Mill VS Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyReview on vertical roller mill in cement industry its

Small Vertical Cement Grinding Mill / Vertical Roller

Product Description Small Vertical Cement Grinding Mill Energy Saving Low Dust Pollution Vertical Cement Grinding Mill produced by China ZK Corp is is a new type of high efficiency, energy conservation and environmental protection of grinding equipment, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw materialsVertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power Vertical Raw Mill for Cement Raw Meal Grinding in Vertical mill The use of vertical mill Vertical mill is an ideal largescale grinding equipment, widely used in cement, electricity, metallurgy, chemical, nongold domestic mining machinery manufacturing enterprises of the mill products are mine and other industriesVertical mill ,Vertical roller mill,Working principle of A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in the cement mills in recent timesReview on vertical roller mill in cement industry its Cement Vertical Mill Structure: The vertical mill consists of a separator rotation system, a separator part, and an upper casing part upper casing with an inspection door and a feed port, a roller device, a transmission device, a tie rod portion, a disc seal, an upper and lower side, a side friction ring, and an unloading material ring, grinding disc adjusting device, air ring adjusting device Cement Vertical Mill for sale

Grinding Fineness Of The Vertical Roller Mill

Vertical roller mill is the key equipment for crushing materials after crushingIt is widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal beneficiation, and glass ceramics and other production industries, dry or wet grinding of various ores and other grindable materials Vertical Roller Mill Capacity:20300 T/H Feeding size:100 mm Output Size:301000 Mesh Brief Introduction: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, espeVertical roller mill,Vertical Grinding mill,Vertical Process introduction The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions It can save 30% of power per ton compared with traditional ball mill At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollutionVERTICAL CEMENT MILL Xinxiang Great Wall The vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium orehow to improve grinding efficiency of vertical roller mill SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALY

China Cement Vertical Mill, Vertical Mill for Raw

ZK vertical roller mill in cement industry price is widely used for micron powder producing The output size can reach 2500mesh (5um), vertical roller mill in cement industry price is suitable to grind the material with middle and low hardness, moisture below 6%, and the material should be nonexplosive and nonflammable 1What is the application area of vertical roller mill in cement Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mineVertical Roller Mill GGBSCement Plant,cement Vertical roller mill is the key equipment for crushing materials after crushingIt is widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal beneficiation, and glass ceramics and other production industries, dry or wet grinding of various ores and other grindable materialsGrinding Fineness Of The Vertical Roller MillGrinding roller is core part of vertical mill Great Wall Steel Casting can provide customized service according to customers’ different processing requirements Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc We gained good reputation from customersGrinding roller for vertical mill Global Manufacturers Application of Vertical Roller Mill Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcVertical Roller Mill

Vertical Mill and Spare Parts vertical mill Grinding

Slijprol voor v ertical mill Gewicht: 20120T Toepasselijk inrichtingen: verticale molens, verticale molens minerale slakken, cement verticale molens, verticale molens staalslakken, nikkel slakken molens, verticale molens grondstoffen en kolen verticale molens Toepassing: Cement, bouwmateriaal, chemische, kolen en anderen Aanpasbaar: JaProcess introduction The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions It can save 30% of power per ton compared with traditional ball mill At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollutionVERTICAL CEMENT MILL Xinxiang Great Wall Vertical Roller Mill Capacity:20300 T/H Feeding size:100 mm Output Size:301000 Mesh Brief Introduction: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, espeVertical roller mill,Vertical Grinding mill,Vertical Mill in cement production, is still not completely replace the main grinding equipment, but also the power consumption and the largest producer of the metal abrasion equipment Improving the grinding efficiency of vertical roller mill, has been a major research topic grinding experts at home and abroadHow to improve the grinding efficiency of vertical ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet Vrm Presentation Mill (Grinding) Cement